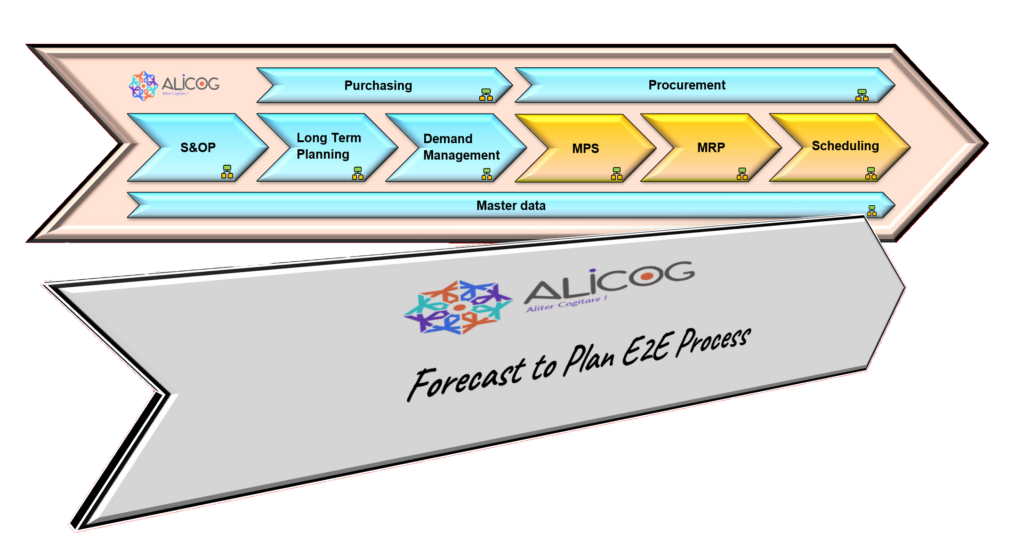

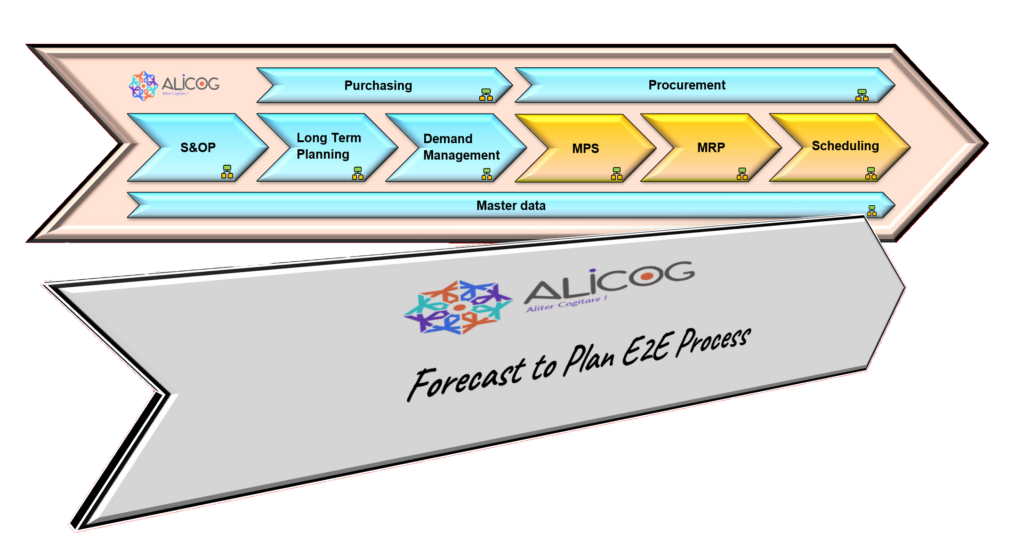

Production planning

After alignment on strategic goals of the company (S&OP), Planning is a fundamental process that organizations use to set objectives, determine actions, and allocate resources to achieve desired outcomes. It involves analysing current conditions, envisioning future goals, and developing strategies to bridge the gap between the two. Planning is essential across all aspects of business, from setting strategic direction to managing day-to-day operations.

In ALICOG we support our customers with the following planning processes:

- Master Production Scheduling (MPS):

MPS is a detailed plan that specifies the quantity and timing of production for each finished product.

It translates the overall production plan into specific schedules for individual products, taking into account customer demand, available production capacity, and inventory levels.

MPS typically covers a short to medium-term planning horizon, often ranging from a few weeks to several months.

The goal of MPS is to ensure that production meets customer demand while optimizing resource utilization and minimizing inventory costs.

- Material Requirements Planning (MRP)

MRP is a systematic approach to determining the materials needed for production and ensuring their availability at the right time and in the right quantities.

It calculates the materials required based on the MPS, bill of materials (BOM), inventory levels, lead times, and production schedules.

MRP generates procurement or production orders for raw materials, components, and subassemblies to support the production schedule.

The primary objectives of MRP are to prevent stockouts, minimize excess inventory, and optimize inventory turnover.

- Detailed Scheduling process:

Scheduling involves determining the sequence and timing of production activities to ensure that resources are used efficiently and production targets are met.

It includes assigning specific tasks to machines, workstations, or production lines, considering factors such as production capacity, setup times, and dependencies between tasks.

Scheduling may cover various aspects of production, including machine scheduling, workforce scheduling, and production order scheduling.

The goal of scheduling is to maximize throughput, minimize idle time, and optimize the flow of materials and information throughout the production process.

In ALICOG we support our customers with the following planning processes:

- Master Production Scheduling (MPS):

MPS is a detailed plan that specifies the quantity and timing of production for each finished product.

It translates the overall production plan into specific schedules for individual products, taking into account customer demand, available production capacity, and inventory levels.

MPS typically covers a short to medium-term planning horizon, often ranging from a few weeks to several months.

The goal of MPS is to ensure that production meets customer demand while optimizing resource utilization and minimizing inventory costs.

- Material Requirements Planning (MRP)

MRP is a systematic approach to determining the materials needed for production and ensuring their availability at the right time and in the right quantities.

It calculates the materials required based on the MPS, bill of materials (BOM), inventory levels, lead times, and production schedules.

MRP generates procurement or production orders for raw materials, components, and subassemblies to support the production schedule.

The primary objectives of MRP are to prevent stockouts, minimize excess inventory, and optimize inventory turnover.

- Detailed Scheduling process:

Scheduling involves determining the sequence and timing of production activities to ensure that resources are used efficiently and production targets are met.

It includes assigning specific tasks to machines, workstations, or production lines, considering factors such as production capacity, setup times, and dependencies between tasks.

Scheduling may cover various aspects of production, including machine scheduling, workforce scheduling, and production order scheduling.

The goal of scheduling is to maximize throughput, minimize idle time, and optimize the flow of materials and information throughout the production process.

In ALICOG, we assist our customers by:

- Assessing current processes and identifying areas for improvement.

- Designing and optimizing planning processes to enhance efficiency.

- Providing training and change management support.

- Monitoring performance and driving continuous improvement.

- Integrating those processes with other supply chain functions.

- Managing risks and enhancing resilience in operations.

For any inquiry/question, we will be more than happy to answers them !

In ALICOG, we assist our customers by:

- Assessing current processes and identifying areas for improvement.

- Designing and optimizing planning processes to enhance efficiency.

- Providing training and change management support.

- Monitoring performance and driving continuous improvement.

- Integrating those processes with other supply chain functions.

- Managing risks and enhancing resilience in operations.

For any inquiry/question, we will be more than happy to answers them !